Why is Case Packing More Suitable for Hotels?

Similar to all businesses hoteliers are focused on the profitability. To increase profits the majority of them try to cut costs. packaging is among the primary elements that they target. Many may believe that bale packing can save on shipping and packaging expenses, however this is an untruth! Although bale packing may appear to be cost effective, it severely can affect the quality of the hotel towels in transport due to the significant compression that is involved. The compression could reduce the quality of towels. However packaging in a case protects the integrity of items. The case packing prevents compression and also the towels are packed in a separate way, making sure they stay in good condition and are ready for usage.

Why You Should Never Choose Bale-Packed Hotel Towels

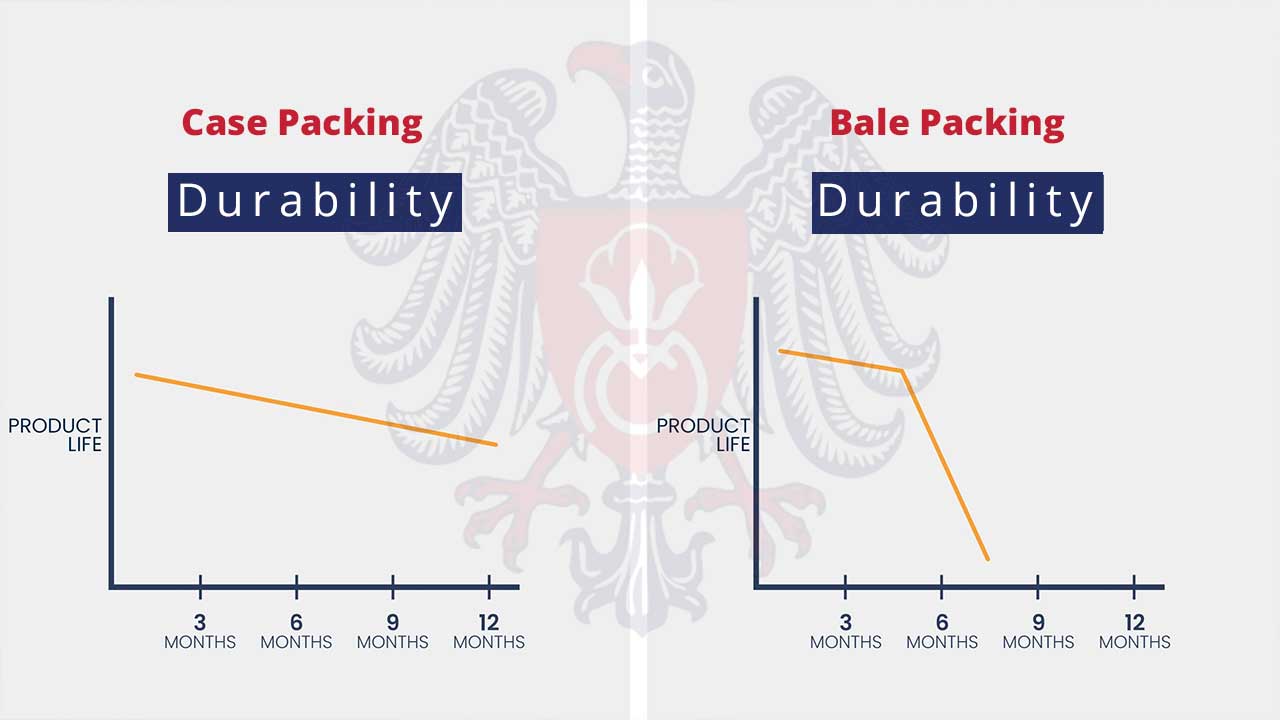

Knowing why hotel towels packed with bales may harm your business is easy. Studies carried out by My Cotton’s team has shown the impact of bale packing on the durability of towels by as much as 30 percent. There are a few negatives to using bale-packed towels- 30% blow to Durability Bale packing is the process of the compression of towels using as much as 150 tons of force. Although this permits shipping massive quantities, it decreases longevity by about 30%.

- Flat, not fluffy: Bale packing flattens towels, removing their softness and fluffiness. The towel that was advertised as fluffy towels may appear more like the appearance of a cloth. This can affect absorbency as well as the softness that your customers would like to see.

- Important Yarn Damage In the process of packing bales, compression creates microtears which reduce the durability of the towel and raise chances of fraying.

How Does Case Packing Maintain the Quality of Hotel Linens?

My Cotton My Cotton, we recommend cases for the packing of sheets and towels for hotels because:- No compression: The case packing process does not include compressing or sealing with vacuum which allows towels to keep their original shape and fluffy.

- Maintained Quality and Fluff: In the absence of compression, towels stay fluffy, soft and immediately available to guests. This ensures satisfaction for the guest.

- Protection From Damage The robust boxes that are used to pack cases offer protection and reduce the risk of being damaged during transport.

Don’t Make a Quick Decision, Make the Right One!

This is a brief comparison of the bale packing of a case and that of a bag:| Factors | Case Packing | Bale Packing |

| Durability | Maintained and protected | Decreases by 30% |

| Fluffiness | Maintained and protected | Loss due to compression that is high |

| Yarn Quality | Maintained and protected | Fraying can result from microtears. |